How We Farm Sea Salt

The Beginning

Between May and late September, we gather seawater from a gorgeous private beach on the south end of San Juan Island, bringing it back to our farm to be filtered and pumped into our evaporation houses.

Fred

Our 50 year old flat bed F700-lovingly named Fred (because the O is missing from FORD on the front), is our hardworking trusty saltwater steed. Load after load of seawater he hauls to the farm throughout the summer.

Our Salthouses

These are our sea salt evaporation greenhouses. Warmed only by the sun. No heaters, no fans, no nothing. Just sunshine and seawater. This is pretty unusual as lots of the artisan sea salt on store shelves is made by boiling seawater with fossil fuels which as you can imagine is very energy intensive.

Filter Time

We filter the seawater coming into our ponds down to 1 micron, resulting in crystal clear, beautiful indoor oceans!

Evaporation Time

This is a freshly filled house. We currently have fourteen of these houses and inside each is a saltwater pond that gets filled once a month during the summer with 1500 gallons of water. It can get very hot in here (130F plus, making evaporation go quickly. The mirror images formed on the water from the greenhouse ribs never get old!

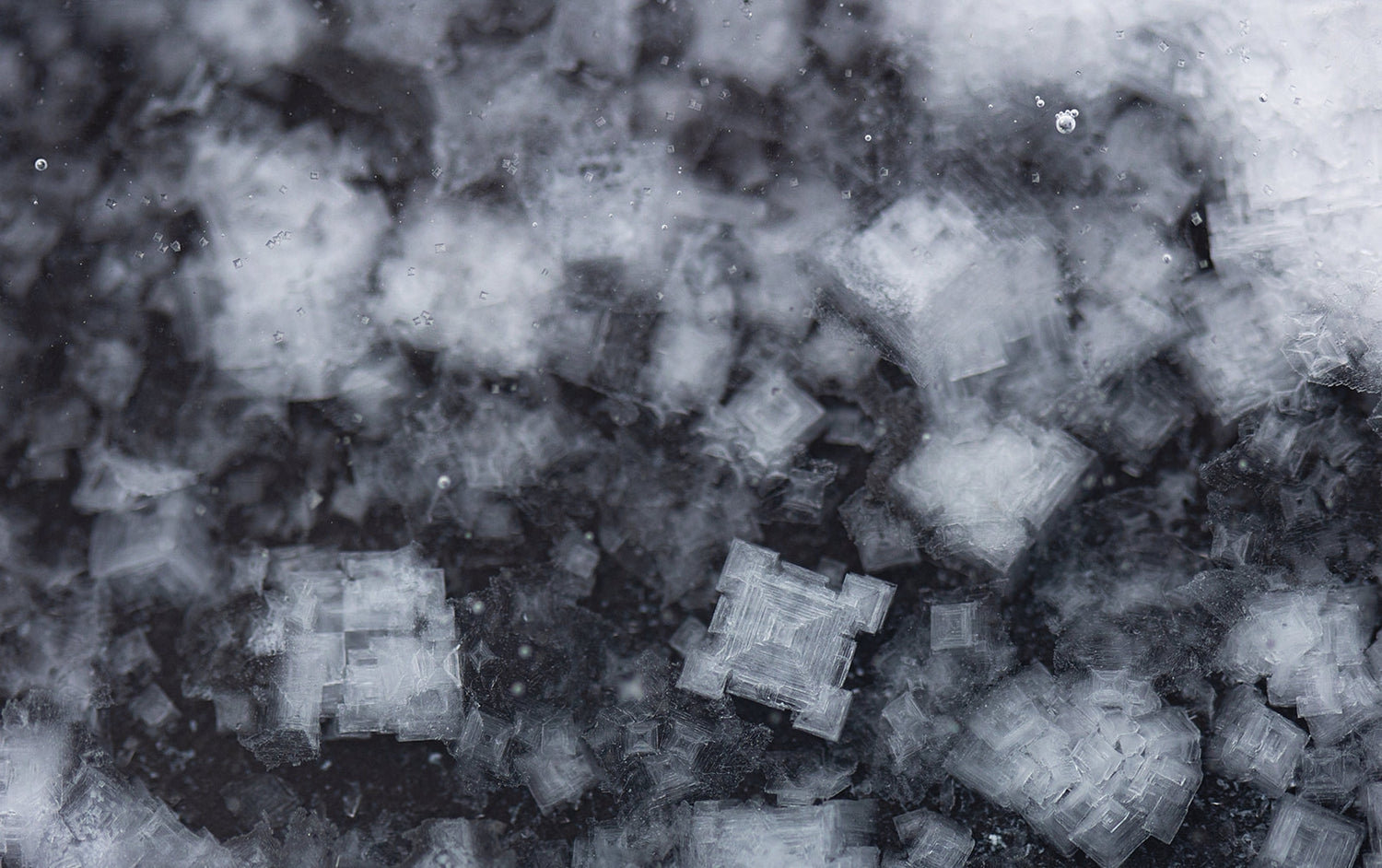

Crystallization Begins

This is our favorite time. When there is still water in the pond but crystals have begun their proliferation. They usually start as tiny inverted pyramids hanging on the surface of the water! You can often catch us just staring into the beautiful chaos of the crystals. It never gets old.

Ready for Harvest

After about a month—on average—the whole pond has evaporated, leaving behind a thick layer of about 350 lbs of sea salt. One of the things that make our sea salt unique is that we let our seawater completely evaporate, which allows the trace minerals naturally present in the ocean to stay in the salt, adding to its briny flavor!

Gathering the Goods

White gold. We farm white gold!

Hand Powered

Harvesting is a bear of a job, hauling bucket after bucket of hot wet salt in greenhouses that can be as hot as 130F during the summer. But we love it. Nowadays our Salt Production Manager Ian or his assistant Izak do almost all this grueling work.

Into the Salt Kitchen

The salt that we gather from the houses comes in an amazing diversity of sizes and shapes, and through drying, sifting, grinding and sorting we are able to get our different grades: flake salt, natural salt, reserve salt, grinder salt, and medium coarse salt. And although we only produce salt during the summer, it doesn't spoil, so we are processing and jarring it all year long.

Into the Spice Kitchen

Once we have our salt processed, the stuff that isn't used for natural salt heads into the spice kitchen where we mix it with over 100 different organic herbs to make our seasonings.

Into the Caramel Kitchen

Our master of flavors Tyler also uses our sea salt to flavor our amazing Salted Honey Caramels. Made with organic butter, organic sugar, organic cream, local honey and of course our sea salt. These are Good Food Award winners and for good reason!

Into the Cookie Kitchen

Our CCO (Chief Cookie Officer) Leah uses our salt (and sometimes smoked salt and smoked sugar) in and on all of her amazing cookies in our shop in Friday Harbor. They are the best cookies in town!

Off to you!

It's a team, family effort from start to finish. Here is Sawyer helping out with the holiday rush.